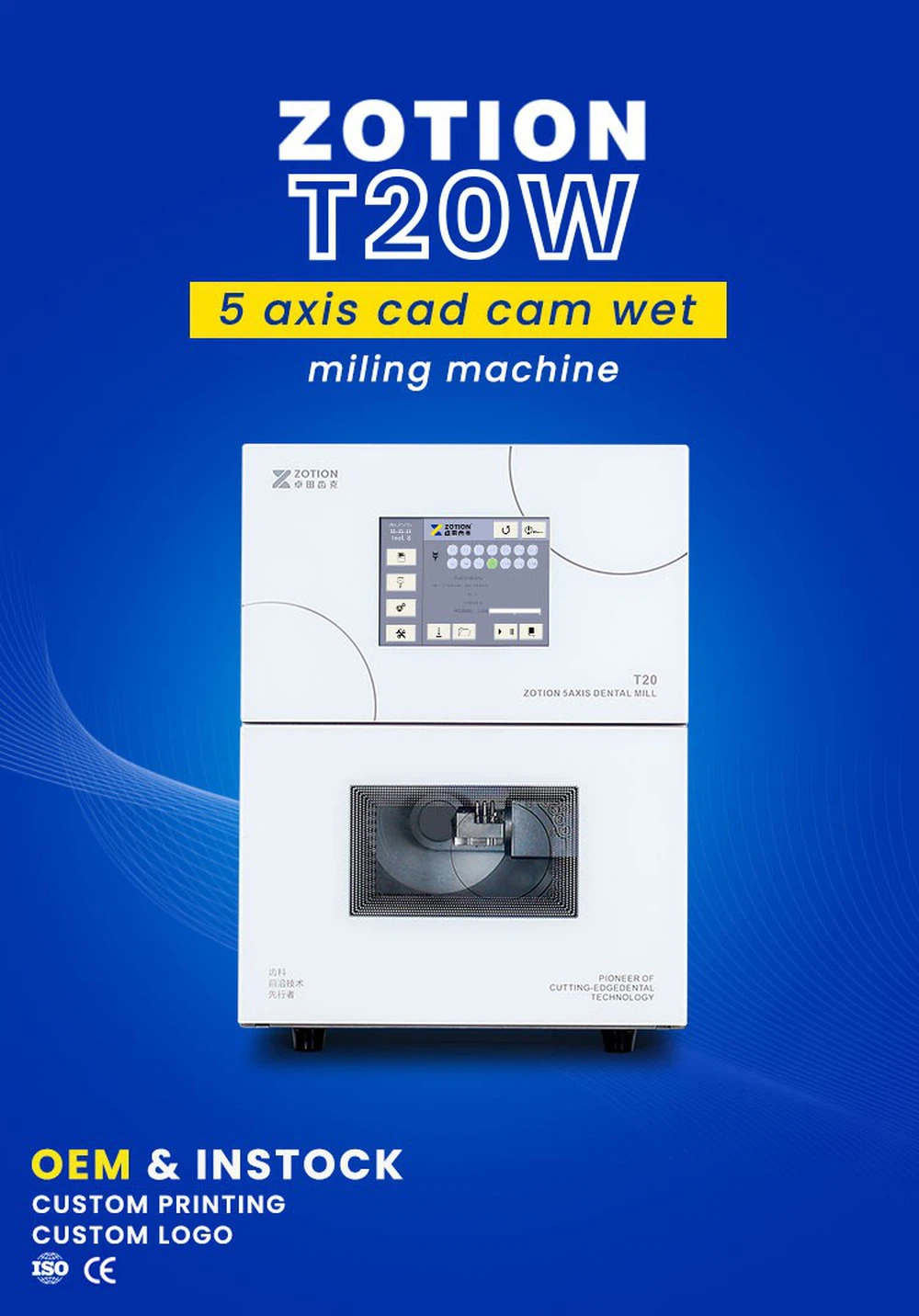

CAD cam CNC Dental Milling Equipment 5 axis Wet Milling Machine

CAD cam CNC Dental Milling Equipment 5 axis Wet Milling Machine T20W, Is a stable, high-precision, high-efficient wet 5Axis milling machine. The equipment is easy to operate, and a new fixture concept design. Bring you the ideal premill abutment and glass ceramic processing solutions.High-precision control and brand-new structural design offer you a stable and efficient processing experience.

- Product Introduction

Products Description

The CAD cam CNC Dental Milling Equipment 5 axis Wet Milling Machine is a high-precision, efficient wet 5-axis milling solution designed for ease of operation and versatile machining. It features an innovative fixture concept that allows milling of pre-ground abutments and glass ceramics. The advanced control and structural design of the CAD cam CNC Dental Milling Equipment 5 axis Wet Milling Machine provide stable and efficient operation, delivering high-quality results. The CAD cam CNC Dental Milling Equipment 5 axis Wet Milling Machine can mill 2 titanium pre-ground abutments or 3 glass ceramic discs at a time. It is equipped with a semi-open clamp (C-CLAMP) that is compatible with 98 mm PMMA discs to meet a variety of milling needs. For enhanced flexibility, the composite bracket supports 6 positions to mill 2 titanium pre-ground abutments or 3 glass ceramics at the same time. The fixture can also be customized to specific titanium pre-ground abutments, expanding its capabilities for precise, multi-material machining.

Products parameter

| products |

|

| Model | T20D |

| Axis | 5 |

| Milling mode | dry |

| Max spindle speed | 60000 RPM/min |

| Spindle power | 850w |

| Spindle cooling | Water cooling |

| Rotation range | A axis: 360° B axis:+25°-135° |

| Number of tool housed | 12 |

| Compatible compressed air | >6pa(No oil and no water) |

| Input Voltage | max.850W,50-60Hz,220ACV |

Products advantages

Number of tools: 12

12 tool capacity allows for greater versatility in milling dental restorations. You can set up a variety of tools to handle different milling operations without having to manually change tools during the process. Reduce downtime and increase productivity.

It enables quick change of different tools required for various tasks such as milling, grinding or finishing within a single cycle.

Large B-axis rotation range (±25° to 135°)

The large rotation range of the B-axis allows for more precise control of milling angles. This is particularly useful when dealing with complex geometries that require bevels or smooth surfaces.

It allows access to hard-to-reach areas of dental restorations, ensuring high precision and smooth surfaces. Reduces the need to reposition the workpiece, improving consistency and quality.

Rotary axis travel (A-axis: ±360°; B-axis: ±25° to 135°)

The ±360° rotation of the A-axis ensures that the machine can mill all sides of the workpiece without manual repositioning, improving accuracy. The wide range of the B-axis further enhances its ability to handle complex designs, especially when making bridges or crowns with undercuts.

Auto-calibration

Ensures the machine is always aligned and calibrated, preventing errors due to misalignment.

Auto-calibration saves time, eliminates the need for manual checks, and reduces human error

Hydraulic buffer door

The advanced hydraulic buffer door design enhances the user experience by providing smooth and controlled door opening and closing. Reduces wear and protects the equipment.

Power-off memory function

If a power outage occurs, the machine does not need to start from the beginning, saving time and ensuring that the workflow is not interrupted.

No need to restart after power outage

Allows the machine to continue milling after power outage.

Reduces waste and improves work efficiency.

Products application

factory

Cover Area

years experience

Exported Countries

Customer Services

Products certificates

Products exhibition

Hot Tags: CAD cam CNC Dental Milling Equipment 5 axis Wet Milling Machine, China, suppliers, manufacturers, factory, customized