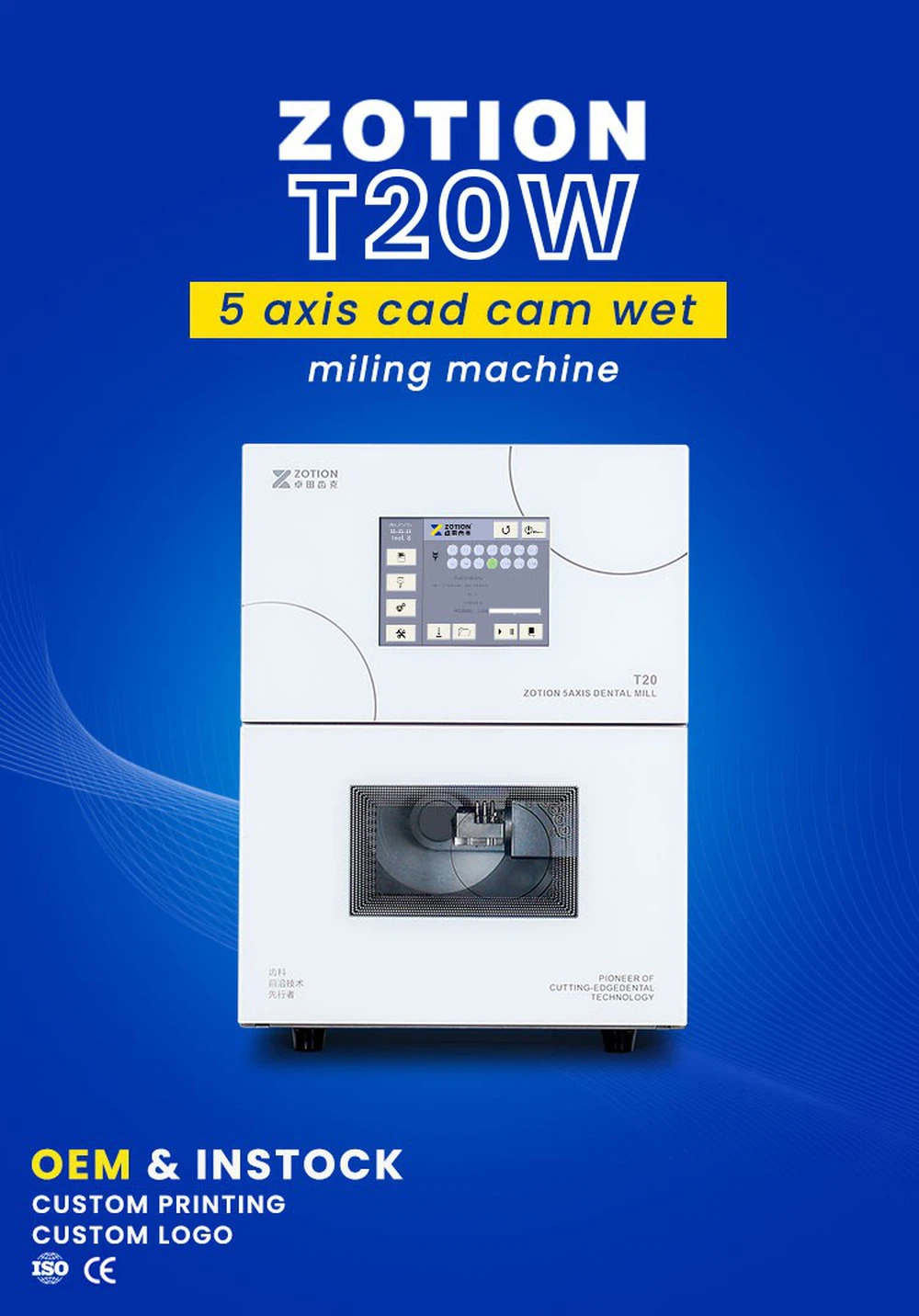

5 Axis Wet dental CAD CAM Milling Machine For Glass Ceramic

5 Axis Wet dental CAD CAM Milling Machine For Glass Ceramic T20W, Is a stable, high-precision, high-efficient wet 5Axis milling machine. The equipment is easy to operate, and a new fixture concept design. Bring you the ideal premill abutment and glass ceramic processing solutions.High-precision control and brand-new structural design offer you a stable and efficient processing experience.

- Product Introduction

Products Description

The 5 Axis Wet dental CAD CAM Milling Machine For Glass Ceramic wet mills glass ceramic blocks, pre-milled abutments and discs made of PMMA, wax or PEEK. The machine offers exceptional quality and precision, thanks to Zotion's 15 years of expertise in the design and manufacture of CNC milling machines.

1. Lightweight and compact design (50KG)

Method: The whole machine weighs only 50 kilograms and is small in size. It can be easily placed in the limited workbench space of a dental clinic or laboratory without the need for additional reinforcement of the load-bearing structure.

Easy to carry, install and maintain, especially suitable for small environments where multiple devices work together, reducing space occupancy.

2. Five-axis motion range (A axis ±360°, B axis +25° to -135°)

Method:

A-axis full rotation: The workpiece can rotate around the horizontal axis without dead angles, avoiding multiple clamping due to angle restrictions.

B-axis large tilt range: The spindle head can be tilted from +25° to -135°, allowing the tool to approach the curved surface of complex crowns/bridges at the best angle.

Actual advantages: There is almost no "undercut blind area", and high-precision processing of deep cavities and undercut structures (such as the occlusal surface of posterior teeth) can be completed in one go, reducing manual finishing.

3. Milling tool life display

Method: Built-in sensors or algorithms monitor the cutting time, load and wear of each tool in real time, and display the remaining life percentage or recommended replacement time through the interface.

Actual advantages: Prevent processing failures caused by excessive tool wear (such as chipping, rough surface), reduce material waste, and optimize tool procurement plans.

4. Power-off memory function (efficiency increased by 80%)

Method: When a sudden power outage occurs, the system automatically saves the current processing coordinates, tool position and remaining programs to non-volatile memory; after power is restored, the user confirms and continues from the breakpoint.

Actual advantages: Avoid expensive materials (such as glass ceramic blocks) from being scrapped due to power outages, save re-clamping and tool setting time, and are especially suitable for long-term unattended processing.

5. STL file processing time display

Method: After loading the STL file, the software automatically estimates the completion time based on the geometric complexity, tool path and material hardness, and updates the remaining time in real time.

Actual advantages: Help users accurately arrange multi-task queues, reasonably allocate equipment resources, and improve overall work efficiency.

6. One-click calibration (no traditional milling block required)

Method:

Automatic probe calibration: Automatically detect tool length/diameter deviation and compensate parameters through contact probe.

Vision or laser tool setting: Replace physical calibration blocks and quickly locate the workpiece coordinate system.

Actual advantages: Simplify the operation process, shorten the preparation time (traditional calibration takes several minutes, one-click calibration only takes a few seconds), and reduce human errors.

7. 850W high-power spindle

Method:

High-speed cutting: Supports high speed (up to 60,000 RPM), combined with high torque, quickly removes hard glass-ceramic materials.

Dynamic stability: Precision bearings and cooling systems ensure minimal vibration at high speeds and maintain surface finish (Ra<1μm).

Actual advantages: The processing time of a single crown can be shortened to 10-15 minutes while ensuring edge accuracy (fitness<20μm).

8. Integrated gripper and automatic tool magazine

Method:

Compact tool magazine design: The tool magazine is directly integrated near the spindle, adopts a turret or chain structure, and supports 8-12 tools.

Quick tool change (<3 seconds): Automatic switching through a robotic arm or pneumatic device, without manual intervention.

Actual advantages: Reduce equipment footprint, support multi-process continuous processing of complex workpieces (such as rough milling-fine milling-polishing), and improve the level of automation.

Products advantages

Products application

factory

Cover Area

years experience

Exported Countries

Customer Services

Products certificates

Products exhibition

Hot Tags: 5 Axis Wet dental CAD CAM Milling Machine For Glass Ceramic, China, suppliers, manufacturers, factory, customized