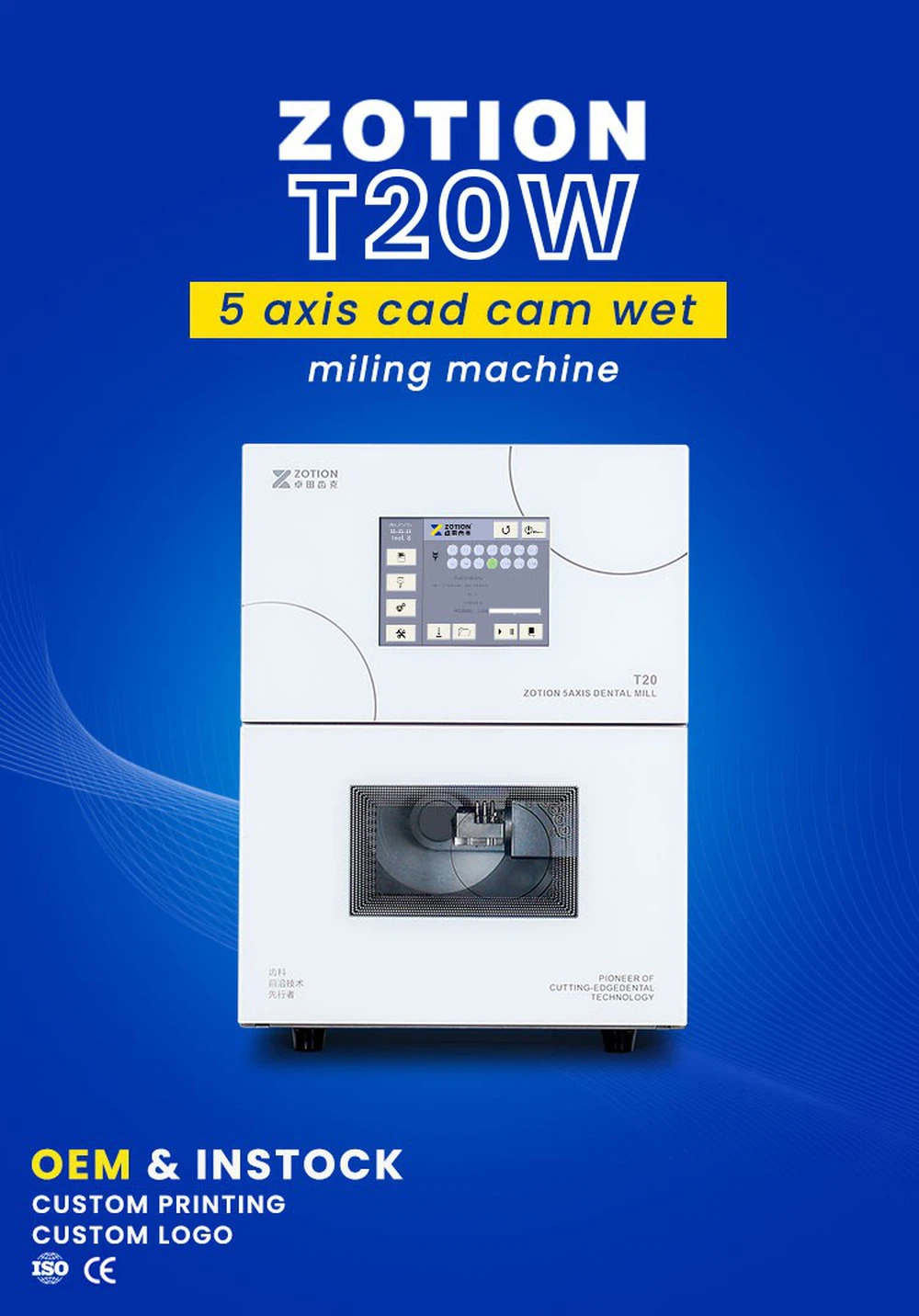

5 axis Dental Cad Cam Wet Milling Machine

5 axis Dental Cad Cam Wet Milling Machine T20W, Is a stable, high-precision, high-efficient wet 5Axis milling machine. The equipment is easy to operate, and a new fixture concept design. Bring you the ideal premill abutment and glass ceramic processing solutions.High-precision control and brand-new structural design offer you a stable and efficient processing experience.

- Product Introduction

Products Description

1.5-axis milling technology:

Multi-angle machining: supports five-axis synchronous motion, suitable for complex dental restorations such as crowns, bridges and inlays.

High precision: provides excellent machining accuracy for perfectly fitting restorations (A-axis: 360°, B-axis: +25° to +135°).

2.Wet milling:

Cooling system: adopts wet milling technology with coolant to reduce heat during material processing, improve machining accuracy and extend tool life (spindle cooling: water cooling).

Material compatibility: suitable for a variety of dental materials, including pmma, wax, peek, titanium posts, metal disks, composite resins and ceramics.

3.High efficiency:

Spindle speed: has a high spindle speed (maximum spindle speed: 60,000 RPM) to improve processing speed and efficiency.

4.User-friendly interface:

Touch screen control: equipped with an intuitive touch screen interface, easy to set up and operate.

Software compatibility: Supports mainstream CAD/CAM software, and can directly import and process design files.

5. High reliability and durability:

Sturdy structure: High-quality mechanical structure and components ensure long-term stable operation.

Easy maintenance: Designed for direct maintenance to minimize equipment downtime.

6. Technical specifications:

Control system: Usually based on Windows operating system, supports multiple languages (Russian, English, French, etc. more than 10 languages) and operating modes.

Products parameter

| products |

|

| Model | T20D |

| Axis | 5 |

| Milling mode | dry |

| Max spindle speed | 60000 RPM/min |

| Spindle power | 850w |

| Spindle cooling | Water cooling |

| Rotation range | A axis: 360° B axis:+25°-135° |

| Number of tool housed | 12 |

| Compatible compressed air | >6pa(No oil and no water) |

| Input Voltage | max.850W,50-60Hz,220ACV |

Products advantages

1. 12-position intelligent tool magazine: complex processes are completed in one go

Multiple processes are seamlessly connected: The 12-position design can simultaneously load roughing, finishing, polishing and other different-purpose tools (such as Φ1.0mm ultra-fine milling cutter), and automatically switch with the preset processing program.

2. B-axis ultra-large rotation range (±25°~135°) and A-axis ±360° full-circle coverage

Complex structure processing without dead angles:

B-axis dynamic tilt angle: supports tilt cutting from -25° to +135°, easily copes with the detailed carving of deep-cavity dentures (such as the occlusal surface of posterior teeth) and multi-angle implant connections, avoiding secondary clamping caused by angle limitations of traditional equipment.

A-axis unlimited rotation: ±360° continuous rotation capability enables the workpiece to be fixed once to complete the circular cutting of the full-mouth denture bracket or the multi-faceted synchronous processing of the personalized base, and the processing efficiency is increased by 40%.

3. Fully automatic calibration system: precision guarantee without human intervention

Laser probe online monitoring:

After each startup or tool change, the built-in laser probe automatically scans the spindle and workpiece position, compensates the tool wear value in real time (accuracy ±1μm), and eliminates manual tool setting errors.

Reduce technical dependence: The laboratory does not need to be equipped with full-time engineers, and ordinary operators can complete the calibration process with one click through the touch screen, reducing the cost of human training by 60%.

4. Hydraulic buffer protection door: double upgrade of safety and life

Silent and durable design:

The hydraulic buffer can absorb 95% of the impact force when the door is closed. Compared with the traditional spring structure, the guide rail wear rate is reduced by 70%, and there is no risk of deformation and leakage in long-term use.

The door seal strip is linked with negative pressure dust collection, and the dust overflow during processing is <0.1mg/m³, which meets the ISO 14644-1 clean room standard.

Emergency brake protection: When the door is accidentally opened, the hydraulic system immediately triggers an emergency stop and saves the processing data to prevent personal injury and workpiece scrapping.

5. Power-off continuation and memory function: zero accidental loss

Industrial UPS emergency power supply:

When a power outage occurs, the current processing program, coordinate axis position and tool information are completely saved to local storage (non-volatile memory).

After power is restored, the equipment automatically continues processing from the breakpoint without re-calibration or material scrapping.

Production traceability support: key parameters before and after power outage (such as spindle load, coolant flow) are automatically generated logs to facilitate quality analysis and process optimization.

Products application

factory

Cover Area

years experience

Exported Countries

Customer Services

Products certificates

Products exhibition

Hot Tags: 5 axis Dental Cad Cam Wet Milling Machine, China, suppliers, manufacturers, factory, customized

You Might Also Like